Design & Development of pharmaceutical forms

Classic parenteral dosage forms: solutions, suspensions, emulsions,…

Parenteral dosage forms for sustained release.

Topical dossage: creams, gels,…

Classic oral dosage forms: capsules, tablets, coated tablets, microgranules,…

Oral dossages forms for suistanable release: hidrophylic matrixes, lipid matrixes, pellets,…

The techniques we use to make the pharmaceutical dosage forms are:

- binder jet printing,

- fused deposition modeling (FDM),

- semi-solid extrusion (SSE),

- stereolithography

Customer benefits

- Design of custom and specific formulations with molecules in development phases for preclinical evaluation.

- 3D printing offers on-demand manufacturing at the point of care with low-cost equipment and one-step processes.

- Printed personalised medicine

Target customer

- Pharmaceutical industry (e.g. nutraceuticals, cosmetics, …).

- Research groups aimed at the development of new drugs and pharmaceutics forms.

- Printlets: Hospitals, Pharmaceutical Companies and Universities.

Additional information

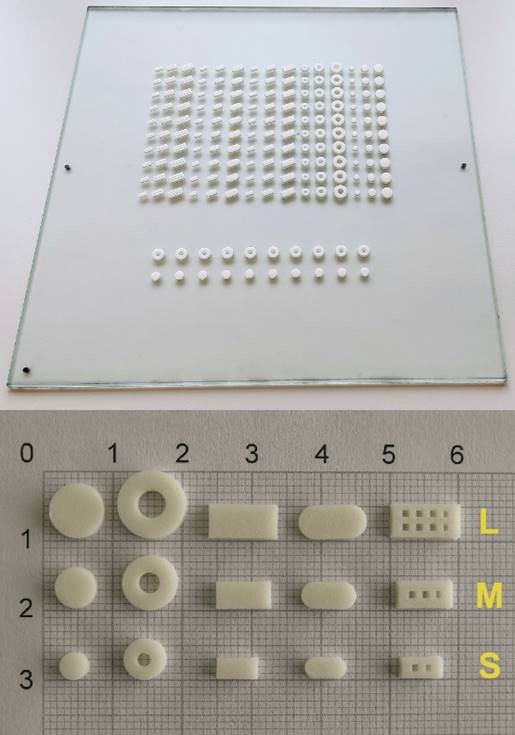

The following is an example of our bioprinted materials, which were used in the first study on 3D screen printing in the fabrication of drug delivery systems:

Reference: D. Moldenhauer, et al. 3D screen printing – An innovative technology for large-scale manufacturing of pharmaceutical dosage forms. International Journal of Pharmaceutics, Vol. 592, 2021, 120096, ISSN 0378-5173, DOI: 10.1016/j.ijpharm.2020.120096.